Ultimate Guide to Inventory Management with QR Codes for Businesses

July 8, 2025

Why QR Codes Are a Game Changer For Inventory

Tracking stock by hand often feels like chasing your tail—endless counts, spreadsheet glitches, and the nagging worry you’ve missed something. Attach a QR code to each product or location, though, and a quick scan turns that slog into a frictionless, data-rich task.

Once you’ve embraced QR codes, the difference is immediate. You’ll see stock levels update in real time, dive into product details on the spot, and wipe out manual entry errors—no more hunting through spreadsheets or wrestling with outdated reports.

Drastically Improved Accuracy And Speed

Human error is the Achilles’ heel of manual counts. One typo in a SKU or a missed line in a spreadsheet can snowball into stockouts or overstocks. With QR codes:

- A single scan locks in the correct item every time

- Full warehouse cycle counts shrink from days to hours

- Confidence soars—you’re no longer guessing, you’re verifying

That boost in precision doesn’t just feel good; it frees up cash tied to “ghost” inventory and keeps popular items in stock.

Instant Access To Rich Product Data

A barcode typically tells you only one thing: the product ID. A QR code goes much further. With one scan, your team can pull up:

- Product SKU, name, and description

- Supplier details and batch numbers

- Received date and expiration for perishables

- Direct links to technical specs or user manuals

Every pallet, box, or bin becomes an intelligent node in your network. Your warehouse team stops hopping between systems—they’ve got everything they need right in their scanner.

As of 2025, 39% of businesses have woven QR codes into their inventory workflows. That’s a clear signal: they’re moving beyond marketing gimmicks and embedding scans into vital logistics.

Traditional vs QR Code Inventory At a Glance

Below is a quick comparison of core metrics—so you can see exactly where QR codes outperform manual methods.

| Operational Aspect | Traditional Method (Manual/Spreadsheet) | QR Code System |

|---|---|---|

| Inventory Accuracy | Prone to typos, misreads, and overlooked items | >99% accuracy with each scan |

| Cycle Count Duration | Multiple days of manual labor | Completed in hours, sometimes minutes |

| Data Centralization | Scattered across files and platforms | Real-time, unified dashboard |

| Labor Costs | High due to repetitive checks | Significantly lower—focus on value-added work |

| Stock Visibility | Delayed updates, blind spots | Instant updates after every scan |

This snapshot highlights how a QR code–driven approach delivers clear operational gains.

Switching to QR codes isn’t just a tech upgrade—it’s a shift from reactive troubleshooting to proactive inventory control.

Laying the Groundwork for Your QR Code System

A solid QR code inventory system is built long before you ever print a label. I’ve seen people jump straight to a QR code generator without a clear plan, and it almost always leads to headaches and backtracking later. This initial planning stage is all about making sure your new system works from day one and can grow with your business.

The very first thing to nail down is what data, exactly, you'll pack into each QR code. This isn’t just a technical detail—it’s a strategic decision that defines how powerful your system will be. The simple route is to just encode a product’s Stock Keeping Unit (SKU). A quick scan pulls up the item. That’s already a huge improvement over manual entry, but you can get so much more out of it.

Let's say you're a food distributor. For you, an expiration date is everything. So, your QR codes should hold not just the SKU, but also the batch number and expiry date. Now, a single scan tells your team exactly which items to pick first, making it easy to follow a First-In, First-Out (FIFO) or First-Expired, First-Out (FEFO) strategy. That simple change can drastically cut down on spoilage.

Static vs. Dynamic QR Codes: What's the Right Call?

Next up, you need to decide between using static or dynamic QR codes. This choice really shapes your system's flexibility and how much work it'll be to maintain down the road.

- Static QR Codes: The data is embedded directly into the black-and-white pattern itself. Once you create it, that information—like a SKU or a plain text batch number—is locked in forever. They are simple, free to generate, and work offline, which makes them perfect for permanent identifiers that will never change.

- Dynamic QR Codes: These are a bit different. They embed a short URL that points to the actual data, which is stored online. This is a game-changer because you can update the destination information whenever you want without having to reprint a single physical QR code.

For most inventory management, I find that static codes pointing to internal product IDs are plenty robust. They just work. However, dynamic codes open up some unique possibilities. Imagine being able to update a link to redirect from a product's basic info to a detailed recall notice if a problem pops up—all without relabeling a single box. A platform like RecodeQR makes managing these dynamic codes incredibly straightforward.

Choosing Your Labels: Don't Skimp on Materials

The physical QR code label is where the digital world meets the real world, and it's often the most vulnerable part of your entire setup. A code that won’t scan is just a useless sticker, so picking the right material for your environment is critical. A standard paper label that’s fine in an office will fall apart in a walk-in freezer or a dusty workshop.

Think about where these labels will live:

- Cold Storage: If you're dealing with frozen goods or refrigerated areas, you'll need waterproof, tear-proof synthetic labels. Materials like polyester or polypropylene are great because they stand up to condensation and stay scannable even in sub-zero temps.

- Warehouse Racking: For marking shelf locations, you want something that lasts. I recommend durable metal or heavy-duty plastic tags. They can take a knock from a forklift and won't fade or peel after years of use.

- Outdoor Equipment: Tracking assets stored outside? You’ll need UV-resistant and weatherproof labels that won't get destroyed by sunlight or washed away by rain.

Pro Tip: Always, always order a sample pack of different label materials first. Test them out in your real working conditions—stick them on your products, throw them in the freezer, leave them out in the sun. This one small step can save you from a massive and expensive mistake.

By thinking through the data you'll encode, the type of QR code you'll use, and the physical labels you'll stick on everything, you're building a truly resilient foundation. This upfront strategic work is what makes the switch to QR code inventory management a smooth, scalable success.

Okay, you've got your strategy mapped out. Now it's time to turn those plans into actual, scannable QR codes that will become the backbone of your inventory system. This is where we move from theory to action, but the goal is to create efficiency, not just more work.

Let’s be honest: manually creating a QR code for every single item in your warehouse is a recipe for burnout and mistakes. It’s not just tedious; it's completely impractical.

The smart move is to use a bulk QR code generator. This lets you take a whole spreadsheet full of product data—SKUs, batch numbers, descriptions, you name it—and turn it into thousands of unique, print-ready QR codes in one shot.

You just need to get your data organized in a CSV file. Each row represents a single item, and each column holds a piece of data you want to encode in its QR code. Upload that file to a bulk generation tool, and you’re golden. For a detailed walkthrough of this process, check out our guide on how to create multiple QR codes at once.

Creating a Consistent Application Protocol

How you stick the labels on is just as important as how you make them. If your labeling is all over the place, you'll create confusion and slow your team down. You need a clear, non-negotiable rule for where every single label goes.

Think about these common scenarios:

- Individual Products: If you're labeling individual boxes, pick a spot and stick with it. For example, always put the label on the top-right corner of the front face. This builds muscle memory, so your team isn't wasting time hunting for the code.

- Warehouse Racking: When you're labeling shelves or bins, consistency is everything. Always place the QR code on the front beam, either to the far left or far right, and at the same height. This makes scanning from a distance with a handheld scanner much, much faster.

- Pallets: For palletized goods, the best approach is to apply a unique QR code label to all four sides of the shrink-wrapped pallet. This guarantees that no matter how the pallet is turned, a team member can find and scan a code without having to walk around it.

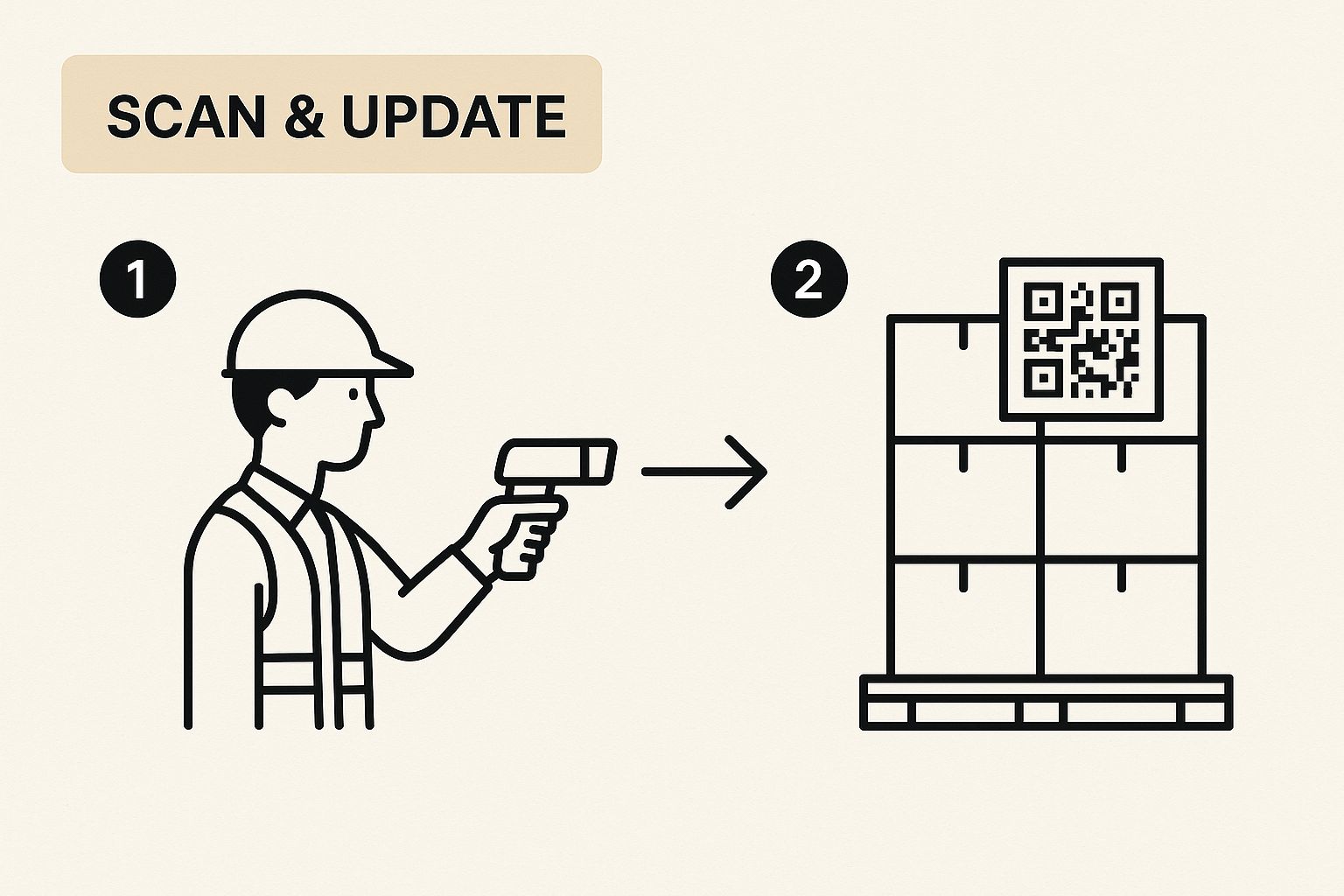

This simple workflow shows how a worker's scan instantly updates the entire inventory system.

The real magic here is that seamless link between the physical act of scanning and the digital record. No more manual data entry, no more typos.

Ensuring Flawless Scans Every Time

A QR code that won't scan is a frustrating roadblock. The good news is that scan failures are almost always preventable with a bit of quality control before you hit "print." Three things matter most: print quality, size, and contrast.

A QR code's reliability is directly tied to its physical integrity. A damaged or poorly printed code can halt a workflow just as effectively as a lost item. Invest in quality labels and printing to safeguard your operational speed.

To avoid these headaches, just focus on these best practices:

- Print Resolution: Always print your QR codes at a high resolution. I recommend 300 DPI (dots per inch) or higher. Low-res printing can make the little black squares blur together, rendering the code unreadable.

- Minimum Size: While QR codes can be tiny, there’s a limit. For most warehouse scanning with handheld devices, a QR code should be at least 1 inch by 1 inch (2.5 cm x 2.5 cm). If you need to scan a pallet rack from the ground, you might need codes as large as 4 inches.

- High Contrast: The classic black-on-white QR code is the most reliable for a reason. Your scanner needs a sharp difference between the dark and light squares. Don't print on busy backgrounds or use low-contrast color combos like gray on light gray or blue on green.

Workflows for New and Existing Stock

Putting your QR code system in place really involves two different jobs: labeling new inventory as it comes in, and retrofitting all the stock you already have.

For new stock, the process is pretty straightforward. You'll just build labeling into your receiving workflow. When a new shipment arrives, your team inspects the items, prints the right QR code labels on-demand, sticks them on according to your protocol, and scans them to officially log the items into your inventory software. Easy.

Retrofitting an entire warehouse is the bigger challenge, but it's totally manageable if you do it in phases. Don't try to do it all at once. Instead, tackle it section by section or category by category to minimize disruption to your daily operations.

The high adoption of scannable codes in commerce proves their value. In fact, around 90% of major global retailers now depend on standardized codes for tracking. This methodical approach to retrofitting ensures your team can adapt without getting overwhelmed.

Your QR code system is only as good as the tools you use to read and manage it. Once your labels are on your products, the next big decision is picking the right scanning hardware and the software that will serve as the brain of your operation.

These choices are critical. They directly shape how efficient your team is, how accurate your data is, and whether you get a real return on this whole project.

https://www.youtube.com/embed/6tXB73HxzSA

The first fork in the road is deciding how your team will physically scan the codes. This choice almost always comes down to two options: using regular smartphones or buying dedicated handheld scanners. There’s no single right answer here—it all depends on your specific workflow and environment.

Dedicated Scanners Versus Smartphone Apps

If you're running a busy warehouse or a fast-moving production line, dedicated handheld scanners are almost always the way to go. These rugged devices are built for one purpose: scanning barcodes and QR codes fast.

They bring some serious advantages to the table, like better durability (they can survive a drop), much longer battery life for full-day shifts, and powerful scanning engines that can read a code from a distance or at a weird angle. Imagine a forklift operator scanning a pallet on a high rack without even getting out of their seat. That's a huge time-saver.

On the flip side, using smartphone apps is a brilliant, low-cost way for smaller businesses, retail stockrooms, or any operation with lighter scanning needs to get started. The biggest win is the cost—you can use existing company phones without shelling out thousands for new hardware. This is perfect for a small clothing boutique tracking new arrivals or a local café managing pantry supplies.

Just be aware of the trade-offs. Consumer phones are more fragile, their batteries might not make it through a full workday of constant scanning, and the cameras can struggle to focus in dim lighting.

The choice between a dedicated scanner and a smartphone really comes down to this: upfront cost versus long-term operational speed. In high-volume settings, the time saved with a dedicated scanner will quickly pay for the initial investment.

QR codes aren't some niche, futuristic tech anymore; they're mainstream. As more and more businesses adopt them, the reliability and ease of use just keep getting better.

This chart from a recent study shows just how widespread QR code adoption has become, proving its acceptance across many different business functions.

This data isn't just a number—it shows that businesses are actively using QR codes to solve real problems, like making inventory management less of a headache.

Finding the Right Inventory Software

Hardware is only one piece of the puzzle. All that data you're scanning needs to go somewhere. It needs a central hub—a software platform that organizes the information and makes it useful. Your options range from simple, DIY setups to powerful, all-in-one inventory management systems.

For businesses just getting their feet wet, you can get surprisingly far with a combination of Google Sheets or Microsoft Excel and an automation tool like Zapier. It's a neat trick: a team member scans a QR code with their phone, and a Zapier "zap" automatically creates a new row in a spreadsheet, complete with a timestamp. It’s a fantastic way to get started with inventory management with QR codes on a shoestring budget.

But as your operation grows, you'll quickly outgrow the spreadsheet. That’s when you’ll want to look at dedicated inventory management software with built-in QR code support. These platforms are designed to manage your stock from purchase to sale.

When you're evaluating software, here are the non-negotiable features to look for:

- Real-Time Syncing: When an item is scanned in the warehouse, the count should update everywhere—instantly. This prevents the sales team from selling an item that was just marked as damaged on the floor.

- Low-Stock Alerts: The system needs to automatically ping you when an item drops below a level you set. This takes the guesswork out of reordering and helps you avoid frustrating stockouts.

- Good Reporting: You need to see the big picture. Look for software that can generate reports on things like inventory turnover, stock aging, and sales velocity. This is the data that helps you make smarter buying decisions.

- User Permissions: Not everyone needs access to everything. You should be able to control who can do what. For instance, you might let warehouse staff adjust stock counts but block them from seeing financial data.

- Integration Power: The software has to play nice with the other tools you use. Make sure it can connect to your e-commerce platform (like Shopify or WooCommerce) and your accounting software (like QuickBooks or Xero). This creates a smooth flow of information and kills manual data entry.

Getting the right hardware and software combination is foundational. A good pairing will make your QR code system feel seamless and almost invisible. A bad one will just create constant headaches for your team.

Weaving QR Codes Into Your Daily Warehouse Workflows

Having a great QR code system on paper is one thing. Actually getting your team to use it so it feels like second nature is a whole different ball game. Success comes down to integrating scans into your core inventory processes so seamlessly that they replace old, clumsy steps with a simple, satisfying zap of a scanner.

Let’s get past the theory and look at exactly how inventory management with QR codes changes the game for everyday warehouse tasks. These aren’t just ideas; they are practical, road-tested workflows you can put into action right away.

Transforming Your Receiving Dock

The receiving dock is your first, best chance to get inventory data right from the start. Think about the old way: clipboards, manually checking items against a purchase order, and then someone eventually typing all that into a computer. Every single step is a place where mistakes can creep in.

With QR codes, that entire process becomes clean and nearly foolproof.

As your team unloads a new shipment, they inspect the goods. Right there, they use a connected printer to generate and stick a unique QR code label on each box or pallet, following your placement rules. A single scan of that new code instantly logs the item into your inventory system, updating stock levels in real time and tying it directly to the correct purchase order.

One quick scan confirms the item, its quantity, and its location—all without a single keystroke. Just like that, you have a perfect digital record from the moment an item walks in the door.

Making Cycle Counts a Breeze

Let's be honest, nobody enjoys cycle counting. The process of regularly auditing specific sections of your inventory is vital for accuracy, but it’s a dreaded task. Manually finding items, counting them, and scribbling on a notepad is painfully slow and riddled with errors.

A QR code workflow completely flips this on its head. An employee simply walks into an aisle with a scanner. They zap the QR code on a bin location, and their device instantly shows the item and quantity that should be there. They do a quick physical count and either confirm the number or adjust it on the screen if there's a mismatch.

This turns a tedious, multi-step chore into a rapid-fire verification process. What used to involve searching a spreadsheet, writing on a clipboard, and then doing data entry later is now done in a single scan. This is where you'll see massive efficiency gains.

The data backs this up. Businesses that bring in QR codes often see an efficiency boost in inventory management of around 30%, mostly by slashing the human errors that come with manual systems.

Perfecting Your Picking and Packing

Order fulfillment is where accuracy is everything. Shipping the wrong item is expensive, it kills customer trust, and it creates a logistical headache with returns. A QR code system is your best defense against these slip-ups.

When a new order pops up, the picker’s handheld scanner shows them exactly what to grab and where to find it. As they pull each product, they scan its QR code. The system instantly verifies it’s the right item for that specific order. If they grab the wrong thing by mistake, the scanner will immediately buzz or flash an alert.

This simple "scan-to-verify" step makes it nearly impossible to pack the wrong product. It’s a powerful, straightforward check that removes guesswork and helps ensure every order that leaves your warehouse is 100% accurate. You can see more clever ways businesses are using this tech in our post about products with QR codes.

Optimizing the Returns Process

Managing returns can easily descend into chaos. You have to identify the product, figure out if it can be resold, and get your inventory numbers updated. QR codes bring much-needed order to this messy process.

When a customer sends an item back, the original QR code on the product tells you everything you need to know: the SKU, the original order number, and even the production batch it came from. A quick scan lets your team process the return in your system instantly.

From there, another scan directs the item to its next stop:

- Scan to Restock: If the item is in perfect shape, a scan puts it right back into your available inventory.

- Scan to Quarantine: If it’s damaged or needs a closer look, a scan moves it to a designated quarantine or repair area in your system.

This workflow keeps returned items from getting lost in the shuffle or, worse, accidentally sent back out to another customer before being properly inspected. It keeps your inventory data clean and completely reliable.

Common Questions on QR Code Inventory Management

Even with the best plan, you're going to have questions once you start putting a new system into practice. I've seen it time and time again. Moving to inventory management with QR codes is no different, so let's tackle some of the most common issues that come up.

What Happens if a QR Code Gets Damaged?

This is probably the number one question I get, and it's a good one. A torn, smudged, or faded QR code can feel like it will bring your entire workflow to a screeching halt, but it really doesn't have to.

The first line of defense is simply choosing the right label material. If your stuff lives in a rough-and-tumble warehouse, use durable synthetic labels. For items in cold storage, waterproof labels are a must. A little forethought here prevents most problems before they start.

Of course, damage can still happen. That's why your backup plan is critical: always print a human-readable number right on the label, usually just below the QR code. This could be the SKU, a short product name, or a serial number. If a scan fails, your team just types that number into the system to find the item. Simple.

A damaged label should be a minor hiccup, not a major roadblock. Building in this simple redundancy—a scannable code and a readable number—ensures your workflow keeps moving no matter what.

As a final fallback, keep some pre-printed sheets of replacement labels for your most common items handy. This lets an employee slap a new QR code on a damaged one in seconds. Any decent inventory software will have a manual lookup feature, making a bad code a complete non-issue.

Can I Start Without Expensive Software?

Absolutely. You don't need to drop a ton of money on a complex platform right out of the gate. You can actually build a surprisingly effective system with tools you probably already use or can get for free.

Here’s a lean, low-cost way to get your feet wet:

- Generate Codes: Use a free online bulk QR code generator to create static QR codes that just contain your product SKUs as text.

- Manage Data: Your master inventory list can live in a shared Google Sheet or Excel file. This acts as your central database.

- Scan and Update: Your team uses free QR scanner apps on their phones. When they move an item, they scan the code to get the SKU, then just update the count in the shared spreadsheet.

This approach immediately gets rid of typos from manually entering long SKUs and lets you prove the concept works. It’s the perfect way to test the waters before you decide to invest in a paid inventory platform.

What Is the Real Difference Between Barcodes and QR Codes?

While they both get scanned, what they can do is worlds apart. A traditional 1D barcode—like the ones at the grocery store—holds a tiny bit of information, usually just a string of numbers for a product ID. It's built for one job: quick lookups.

A 2D QR code, on the other hand, is a data powerhouse. It can hold thousands of characters. This means a single scan can give you way more than just an ID.

| Feature | 1D Barcode (UPC/EAN) | 2D QR Code |

|---|---|---|

| Data Capacity | Low (around 20-25 characters) | High (over 4,000 characters) |

| Data Types | Alphanumeric (mostly numbers) | Alphanumeric, URLs, binary data |

| Information Stored | Typically just a Product ID (SKU) | SKU, batch number, expiry date, URL |

| Error Correction | None or very limited | High (can be read even if damaged) |

| Scan Direction | Must be scanned horizontally | Scannable from any angle |

This bigger capacity is what makes QR codes so useful for logistics. If you want to dive deeper into how this works, check out our complete guide to QR code inventory management.

How Do I Label Items That Are Too Small?

This comes up all the time in industries like electronics, jewelry, or small parts manufacturing. Trying to stick a tiny label on an individual screw or a small component is just not practical.

The solution is to stop thinking about labeling the item and start thinking about labeling its container.

Instead of trying to tag individual parts, you apply the QR code to the bin, tote, or shelf location where they are stored. The code then represents the type of product inside. When an employee needs to do a count, they scan the bin's QR code and then do a physical count of the items to update the quantity. This kind of location-based tracking is a super effective and widely used strategy.

Ready to take control of your inventory with powerful, flexible QR codes? At RecodeQR, we make it easy to generate, manage, and track dynamic QR codes that adapt to your business needs. Start your free trial today and see how simple it is to build a smarter inventory system. Visit us at https://recodeqr.com to learn more.

Ready to create your QR code?

RecodeQR is the easiest way to create QR codes you can track and edit anytime.

Free 3-day trial. No credit card required.